Timber acclimatisation

Timber floors and wood – moisture relationship

by Hilston Timber Floor’s expert, Jim Hilston

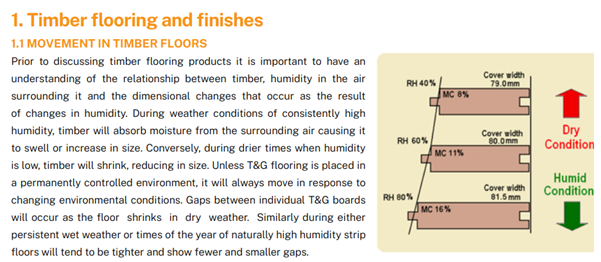

Timber floor boards expand and contract in width with increase and decrease in moisture content. The moisture content is calculated as a percentage of the mass of the board.

From a log, rough cut boards are produced, and dried to become useful for our purposes. At around 30 per cent moisture content (fibre saturation point) the boards begin to shrink in the width as water is removed from the cell structure.

The boards then shrink at a uniform rate – each percentage of moisture reduction causing a consistent shrinkage rate – until the drying achieves the intended moisture content range.

This manufactured moisture content is that at which the board is likely to remain stable within the environment of its intended use. For example, timber flooring to be used internally in Australia is required by Australian Standards (AS 2796.1) to be dry within a range of 9 – 14 per cent moisture content. This moisture content range represents a reasonable range in which timber floors will perform successfully in most moderate climate conditions in Australia. It is important to note that flooring may be manufactured to be predominately at either end of that scale, and the site climate conditions may also be towards one or the other end of the scale (or outside that scale in more extreme climate locations). With this in mind, we can see that it is possible that we could be laying a floor into an internal environment with a 5 or 6 per cent variation between that climate and the corresponding moisture content of the flooring, and this will cause us problems!

The moisture content of the in-service flooring can vary quite significantly with relative humidity (RH) conditions. This can be related to weather and climate conditions or individual site conditions. For example a timber floor will perform differently in Cairns, as to Canberra, or even between the upper and lower floors of the same house!

The diagram below is taken from the Australasian Timber Flooring Association publication “Solid Timber Flooring. Industry Standards” November 2022, and offers a brief explanation of this dynamic.

Acclimatisation – What is it, and why might it be necessary?

Acclimatisation is a process in which the wood may be stored on site for a period of time to allow the moisture content of the flooring to become equalised to the anticipated in service climate conditions.

We must be vigilant regarding the moisture content of our flooring, ensuring there is some measure of equality between new flooring and the climate of the building or rooms into which we are installing. The moisture content at which the timber is most stable in its environment is known as its Equilibrium Moisture Content, or EMC.

A new floor will expand or contract to greater and lesser degrees when achieving equalisation and, if there is great disparity between the in-service RH and the moisture content of the installed flooring, the result may well present a problem, as the floor becomes accustomed to its new climate environment! Either shrinkage and big gaps at board edges with dry conditions, or expansion related performance concerns such as peaking, buckling, squeaking etc., with moister conditions. Timber floors have been responsible for very serious structural damage to buildings when the boards have expanded and met obstructions.

The photos below show a crack in an external wall that is caused by pressure in the internal timber flooring related to increased moisture content, and subsequent board expansion.

Floorboards buckling off a joist subfloor structure as shown in the photos below - are not an unusual occurrence.

Manufacturers have an obligation to produce timber flooring at nominal widths within the range of 9 per cent – 14 per cent moisture content, but most aim for a tighter range and frequently achieve between 10 per cent and 12 per cent. This range is eminently suitable for installation into many locations on the East Coast of Australia, but would be unsuitable for installation into a home in Far North Queensland where the RH conditions are much higher and EMC is around 14 per cent and a floor manufactured at 10 – 12 per cent MC will take up moisture in the prevailing conditions, expand, and potentially cause some problems.

Is acclimatisation always necessary?

And so here we come to the question of acclimatising our flooring prior to laying. Is it really necessary or not? The answer is no, but great care must be taken in understanding the delivered moisture content of our flooring, and the anticipated in-service climate conditions.

In many Australian locations it is wise to plan to install the flooring during mild weather conditions, and without acclimatisation, as the ongoing site conditions are suitable for flooring manufactured at 10 – 12 per cent MC , whereas in the north we would be acclimatising the flooring by storing on site until equalisation has been achieved and this may take several weeks, depending on the prevailing conditions.

Can we acclimatise incorrectly?

What happens if we acclimatise in the wrong conditions? Lets say we are in South East Queensland and intend to install into a new building which does not have air-conditioning or climate control operating. The flooring is delivered in November and the weather is unseasonably hot and dry. The flooring is stored on site for two weeks and during this time the average moisture content drops from 10 – 12 per cent to 9 – 11 per cent. That goes with board shrinkage of around .25mm. The floor is manufactured at 80mm cover width and installed with average board widths at 79.75mm.

Our floor is laid and then goes through December and January while the building works are completed, and the weather remains unusually warm and dry. The homeowners take occupation during February and begin using their showers and opening the house to external conditions and then we get a good solid downpour. Nothing out of the ordinary. Just good rainfall. The house is already undergoing an increase in the internal relative humidity with use, the floorboards have already expanded a little and with the rainfall the internal RH jumps and the EMC heads north to 13 per cent. Even 12 per cent. Our flooring which was installed at 10 per cent and under 80mm width, having been carefully acclimatised, now wants to grow by over 0.5mm per board. That’s a lot!! 10 boards equals 5mm! Over 6 meters the growth is more than 30mm. Australian Standards require 10mm at each perimeter and intermediate expansion allowance when the floor width exceeds 6m. So we have 10mm of growth that needs to be accommodated, beyond that which has been anticipated and allowed for during installation. Where does that growth go? Into problems. Walls being pushed out, floors buckling off joists, internal structures being damaged.

Is acclimatisation necessary?

Is acclimatisation necessary in every circumstance? No. But you MUST know the climate environment in which you are going to lay a timber floor, acclimatise the flooring IF required, and be VERY careful of the conditions existing during acclimatisation, if this process is required.